A Guide for Custom Drone Component

Whether you’re in the drone industry or looking to customize specific drone components for your business, understanding the key parts of a drone is crucial. This knowledge will not only help you in sourcing the right components but also in ensuring your drone designs are optimized for performance, durability, and specific applications.

In this article, we’ll break down the main parts of a drone, focusing on quadcopters—the most commonly used models in commercial and industrial applications. This guide will give you insight into the customizable elements, helping you make informed decisions when working with a supplier to develop tailor-made drone solutions.

Key Customizable Components of a Drone

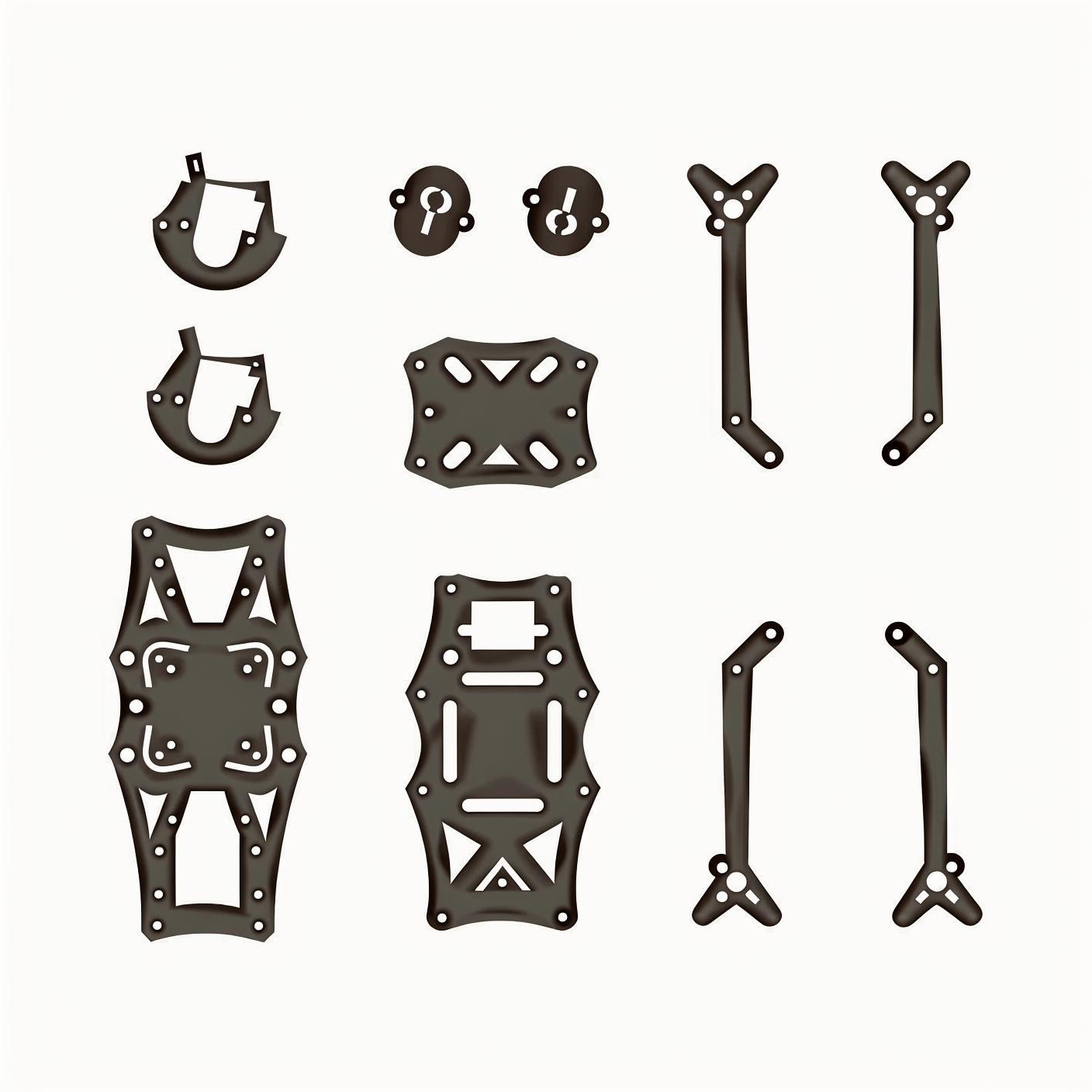

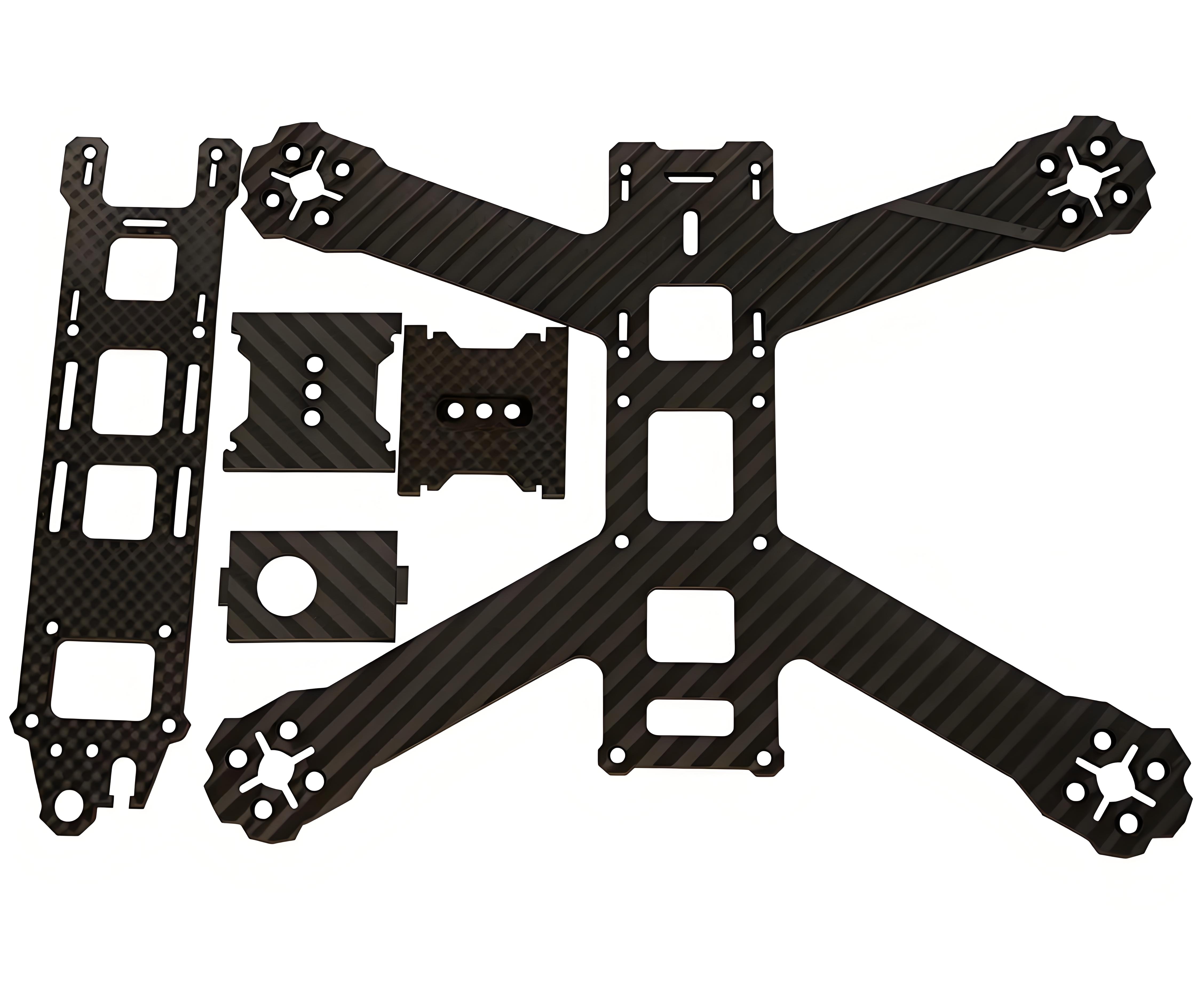

- Frame/Chassis

The frame is the backbone of the drone and one of the most customizable components. It’s the structure that holds all the parts together and largely determines the drone’s size and strength. For custom designs, you can choose from materials like carbon fiber for lightweight durability or aluminum for heavy-duty applications. Customizing the frame can also optimize the drone’s aerodynamics based on your specific use case—whether for longer flight times, higher payloads, or enhanced maneuverability.

- Arms

The arms of a drone, which hold the motors, are often an area where customization is key. Longer arms increase stability, making them ideal for drones carrying heavier loads, while shorter arms enhance maneuverability for racing or agility-focused drones. Depending on the drone’s purpose, the arm design and material can be customized to strike the right balance between durability and weight.

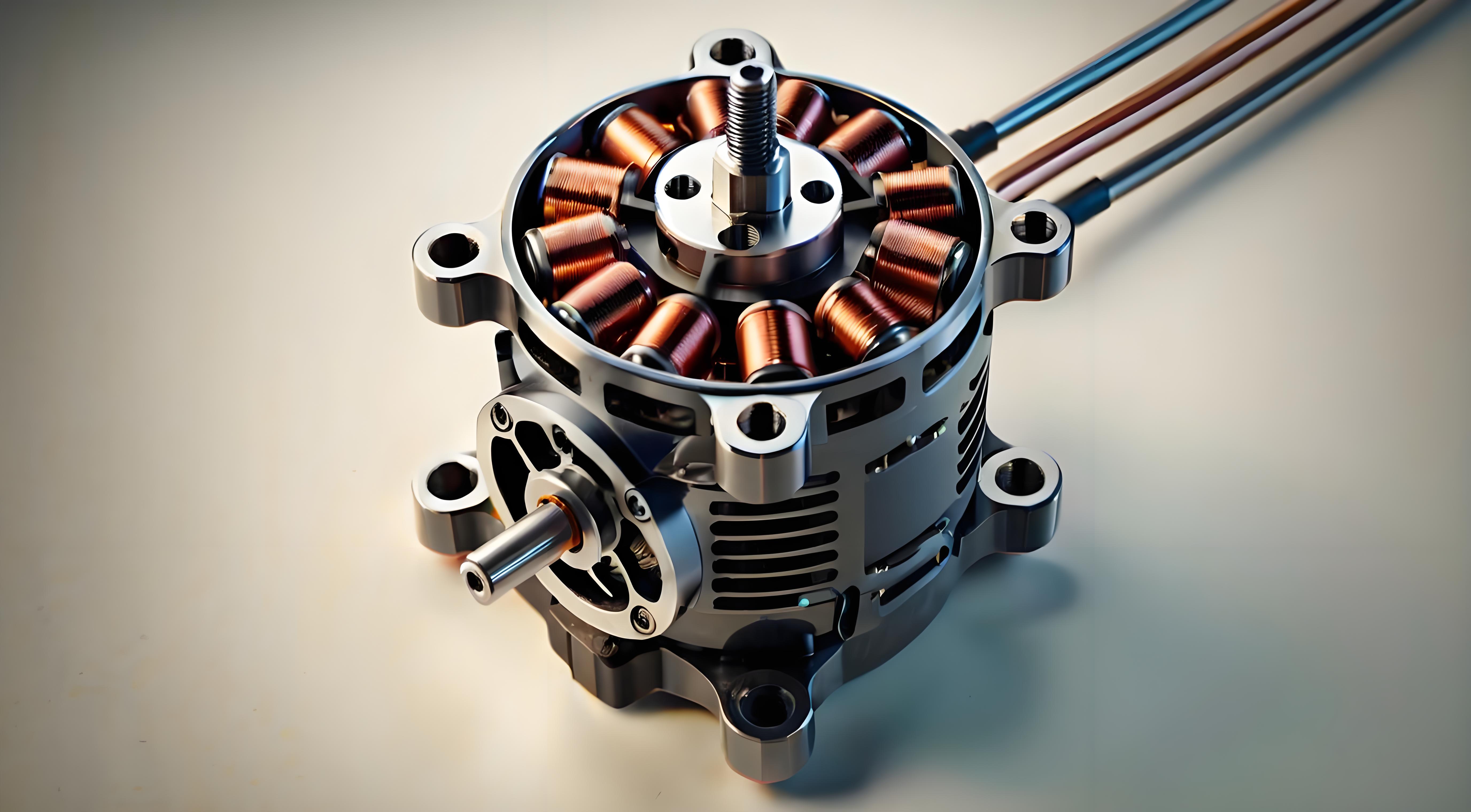

- Motors

Motors are crucial for lifting the drone and controlling its flight. When customizing a drone, motor selection can be based on power output, efficiency, and weight. For drones carrying cameras or other payloads, choosing the right motor is essential to ensure smooth flight and extended battery life. Higher-end brushless motors, for instance, can offer better performance for industrial applications.

- Propellers

Propellers are integral to the drone’s lift and stability. Customizing the propeller size, material, and pitch can dramatically impact flight performance. Drones designed for heavy lifting will benefit from larger, sturdier propellers, while drones built for speed and agility might opt for smaller, lighter ones. Propeller customization can also reduce noise levels and improve energy efficiency, depending on your specific needs.

- Battery

Battery selection is one of the most important decisions when customizing a drone. Li-po batteries are standard due to their lightweight and high-energy capacity, but depending on your application—whether it’s long-range surveillance, extended flight times, or high-energy output for larger drones—you may need to customize the battery size and configuration. - Flight Controller

The flight controller is essentially the “brain” of the drone, managing data from various sensors and transmitting signals to the motors. Customization options for flight controllers can include integrating advanced features like obstacle avoidance, enhanced GPS capabilities, and specific flight modes tailored to your operational requirements. - Electronic Speed Controllers (ESCs)

ESCs control the power sent to the motors and are a vital component for fine-tuning your drone’s speed and maneuverability. Customized ESCs can be selected based on the required power load, responsiveness, and specific flight dynamics, allowing for a more tailored flight experience depending on the drone’s purpose. - Sensors

Customizing the sensor array is critical for drones with specific tasks, like aerial photography, mapping, or agriculture. Some of the commonly used sensors that can be tailored include:- Speed Sensors: Adjust for precision flight control.

- Altitude Sensors: Essential for maintaining flight safety in areas with altitude restrictions.

- GPS and Position Sensors: For applications requiring precise location tracking and automated flight paths.

- Camera and Gimbal

The camera is one of the most customized components for drones used in photography, surveillance, or industrial applications. Options range from standard HD cameras to multispectral or thermal imaging cameras. A gimbal is often added to stabilize the camera, especially for drones capturing high-quality, steady footage. Customizing these elements will depend heavily on the intended use of the drone, whether for high-resolution film production or environmental monitoring.

- Landing Gear

Custom landing gear can enhance the functionality and safety of your drone, especially if it’s designed to carry heavy or sensitive payloads. Adjustable landing gear, shock absorption systems, or retractable gear can be incorporated based on the specific needs of your drone’s mission.

Additional Custom Add-ons

Beyond the standard components, additional customization options are available to suit specialized applications:

- Payload Delivery Systems: Custom-built drones for delivery can integrate specialized cargo hold systems.

- FPV Goggles: For racing drones, a fully customized FPV (First-Person View) system offers real-time visual feedback to the pilot, enhancing control during high-speed flights.

- Multispectral Cameras: Used in agricultural drones to monitor plant health, these cameras can be integrated to meet specific data requirements.

Material Choices for Customization

The choice of materials plays a pivotal role in the overall performance of a drone. For example:

- Carbon fiber is popular for its lightweight and high strength, ideal for both recreational and commercial drones.

- Aluminum or magnesium alloys may be used for drones requiring extra durability, such as in heavy-duty industrial tasks.

Depending on your drone’s intended use, each component can be customized with specific materials to maximize performance while minimizing weight.

Industry Trends and Case Studies in Drone Customization

In today’s rapidly evolving drone market, customization is becoming increasingly essential. Whether in logistics, agriculture, or urban air mobility (UAM), customized components can greatly improve drone performance. Here are some examples:

1. Drones in Logistics

The logistics industry is embracing drones for rapid delivery, especially in remote areas. Leading companies like Amazon and UPS are experimenting with drone delivery. These drones often require long-lasting batteries, lightweight frames, and powerful motors to meet the demands of longer flight times and heavier payloads. Customized parts, such as high-efficiency power systems, can make all the difference in keeping up with the rigorous demands of the logistics industry.

2. Drones in Agriculture

Agricultural drones are increasingly popular for tasks like crop monitoring, irrigation management, and pesticide application. Custom components such as multispectral cameras and sensors can provide critical insights, including detecting crop diseases, monitoring soil moisture, and analyzing crop health. By incorporating the right technology, farmers can reduce costs and improve yields through precise and targeted interventions.

Case Study: Precision Agriculture Drones A large-scale farming enterprise required a custom drone solution to monitor thousands of acres of crops. By integrating specialized cameras and sensors, the drone helped the company detect pest infestations and water stress areas early, optimizing irrigation and pesticide use, and ultimately improving crop yield by 15%.

3. Urban Air Mobility (UAM) and the Future

The concept of urban air mobility, which includes flying taxis and drone-based cargo transportation, is gaining traction. These drones must be highly efficient, with customized high-capacity batteries, advanced flight control systems, and ultra-light frames to carry heavier loads over longer distances. Companies exploring UAM solutions are working closely with suppliers to develop custom drone components to make safe and reliable urban air transport a reality.

Future Technology Trends for Custom Drones

As drone technology continues to advance, customization plays a vital role in adopting future innovations. Some of the emerging technologies that will likely shape the next generation of drones include:

- AI-Powered Flight Systems: Autonomous flight capabilities, powered by AI, will allow drones to navigate complex environments and avoid obstacles without human intervention. Customizing sensors and flight controllers will be key to making AI flight systems work seamlessly.

- 5G Connectivity: As 5G networks expand, drones will benefit from real-time data transmission, allowing for better remote control and monitoring. Custom communication modules designed for 5G will ensure drones stay ahead of the curve.

Conclusion

When sourcing custom drone components, understanding the function and potential for customization in each part is critical to ensuring optimal performance. Whether you’re looking to build drones for industrial, commercial, or recreational purposes, customizing key elements such as motors, propellers, cameras, and flight controllers allows for tailored solutions that meet your specific operational needs.

Working closely with a reliable drone component manufacturer (Leanplans of Course!) ensures that each part is built to your specifications, helping you achieve the right balance of performance, durability, and functionality.

Get a Free Quote!

Leave your contact details, or directly visit our online quoting platform to experience the future of material selection and production. Get expert material evaluations, tailored DFM analysis, and fast 24-hour production turnaround.

- Free Quote: Upload your designs, and our AI-powered engine will generate a custom quote in seconds.

- Talk to an Expert: Connect with one of our engineers via WhatsApp for immediate assistance.