Copper vs. Brass: A Comprehensive Guide

Copper is a widely used metal known for its excellent electrical conductivity, thermal conductivity, and malleability, making it essential in machining applications. It plays a critical role in industries such as automotive, aerospace, and electronics. While brass and copper share subtle differences that can be hard to discern with the naked eye, designers often find it challenging to distinguish between the two during material selection. Despite their similar properties, they differ significantly in elemental composition and other characteristics.

This article will explore the types, properties, and applications of commonly used copper materials in machining, provide guidance on how to differentiate between brass and copper from a materials perspective, and offer material selection tips along with typical processing workflows.

Delving into Copper: The Ancient Metal

As one of the earliest metals discovered, copper holds a unique place in human history. Join us on a journey through the world of copper as we explore its history, properties, uses, and manufacturing processes.

Copper, represented by the symbol ‘Cu’ in the periodic table, is a malleable metal renowned for its excellent thermal and electrical conductivity. It occurs naturally in a usable metallic form, which led to its discovery in prehistoric times.

What are the main properties of copper?

Copper is renowned for its distinctive reddish-brown color and possesses several characteristics that make it a preferred choice for various applications. Key properties include:

- High Electrical Conductivity: Copper’s conductivity ranks second only to silver, making it ideal for electrical applications.

- Excellent Thermal Conductivity: Its superior heat transfer capabilities make it suitable for cookware, radiators, and heat exchangers.

- Malleability and Ductility: Copper can be drawn into fine wires and hammered into thin sheets without breaking.

- Corrosion Resistance: When exposed to the environment, copper forms a protective green patina that shields the underlying metal from further corrosion.

- Antimicrobial Properties: The surface of copper is inhospitable to microorganisms, making it ideal for high-hygiene areas like hospitals.

Given these properties, copper is utilized across various industries, with common applications including electrical wiring, roofing, plumbing fixtures, and heat exchangers. Its antimicrobial features are particularly beneficial in healthcare settings.

Manufacturing Copper

Copper is typically extracted from copper ores through a process involving roasting, smelting, and refining. This journey begins with mining and progresses through flotation concentration, furnace smelting, electrorefining, and finally shaping for various applications.

Process Steps:

- Mining: Copper ore is extracted from open-pit mines.

- Concentration: The ore is crushed and enriched through flotation.

- Smelting: The concentrate is heated in a furnace to separate copper from other elements.

- Electrorefining: An electric current is passed through the metal to purify it.

- Shaping: Refined copper is cast into various forms for different applications.

Advantages of Using Copper in Rapid Prototyping

Copper is an excellent choice for rapid prototyping due to several key advantages. Its outstanding corrosion resistance makes it suitable for diverse environments, ideal for applications such as CNC fixtures, roofing, and circuit boards. The material’s malleability and ductility allow it to be easily shaped into various forms, facilitating intricate designs during CNC machining. Additionally, copper’s high recyclability enhances sustainability, enabling recycled components to retain significant value. With superior electrical conductivity, copper is favored in the electrical industry for applications like superconductors and microchips. Lastly, compared to more expensive metals like titanium, copper offers a cost-effective option for many prototyping projects.

Disadvantages of Copper in Rapid Prototyping

While copper and its alloys have significant advantages, some drawbacks arise when compared to other materials. Although copper is often more economical than steel, it tends to be pricier than plastics. Furthermore, while copper is flexible, plastics generally offer better ductility and machinability. Therefore, it’s essential to understand copper’s properties and processing methods, and consider whether other materials might be more suitable for your rapid prototyping needs.

Brass: More Than Just Another Alloy

While copper is a fundamental element, brass is an alloy formed by combining copper and zinc in varying proportions. To fully appreciate brass, we must delve into its composition, creation, and the diverse applications it serves.

Brass is primarily composed of copper and zinc, with zinc content ranging from 5% to 45%, resulting in different types of brass with varying properties. Certain brass types also include other elements like lead or tin, imparting specific characteristics that enhance their utility.

Main Properties of Brass

Brass possesses a range of characteristics that vary based on its composition, including:

- Color: Brass has a gold-like appearance, becoming lighter with increased zinc content.

- Machinability: Certain types of brass, such as free-cutting brass, are easy to machine due to the addition of lead.

- Corrosion Resistance: Similar to copper, brass is resistant to corrosion, though the level of resistance varies with the type of brass.

- Acoustic Properties: Brass resonates well with vibrations, making it ideal for musical instruments.

Due to its versatility, brass finds applications across various industries. It is widely used in instruments like trumpets and saxophones, as well as in decorative items, plumbing fixtures, ammunition casings, and electrical connectors.

Brass Manufacturing Process

Brass is produced through either casting or forging. The casting process involves pouring molten brass into molds, while forging entails mechanically working the brass to create sheets, wires, or pipes.

Process Steps:

- Melting: Copper and zinc are melted together in a furnace to create a molten metal mixture.

- Alloying: The molten metal is then mixed to form the brass alloy, ensuring a uniform composition.

- Casting/Forging: The molten brass can either be cast into specific shapes or forged into sheets, wires, or tubes, depending on the desired final product.

- Finishing: Brass products undergo finishing processes such as polishing or painting to enhance their appearance and performance.

Advantages of Brass

Brass offers several compelling advantages, making it a preferred choice in various applications. Its ease of machining, especially with grades like C-360, ensures high-speed processing with minimal tool wear, significantly reducing production time. The diverse properties of brass allow manufacturers to tailor its characteristics—such as hardness and strength—by adjusting the ratios of its components, ensuring optimal performance for specific parts. Additionally, brass provides excellent dimensional stability during CNC machining, making it suitable for precision applications.

Disadvantages of Brass

Despite its advantages, brass has some drawbacks. It is prone to dezincification and stress corrosion cracking, especially in humid conditions. Its electrical and thermal conductivity is lower compared to metals like copper, which can limit its applications. Furthermore, while brass is known for its machinability, safety concerns arise from certain alloys that contain lead, posing health risks due to airborne particles during processing. Additionally, machining brass at high temperatures can produce zinc oxide fumes, which may lead to metal fume fever, a temporary illness resembling the flu. Understanding these factors is crucial for effective use of brass in manufacturing.

Weight, Appearance, and Price of Brass

- Weight: Brass is denser than many other metals, with a specific gravity typically around 8.4 to 8.7 g/cm³. This makes brass components relatively heavy, which can be an advantage in applications where durability and stability are desired.

- Appearance: Brass has a distinctive golden-yellow color, which can vary based on the zinc content. Its shiny finish gives it an attractive look, making it popular for decorative items, fixtures, and jewelry.

- Price: The cost of brass varies based on factors such as alloy composition and market conditions. Generally, brass is more affordable than premium metals like titanium but can be more expensive than common materials like steel or plastic. Its price also fluctuates with changes in the prices of its base metals, copper and zinc.

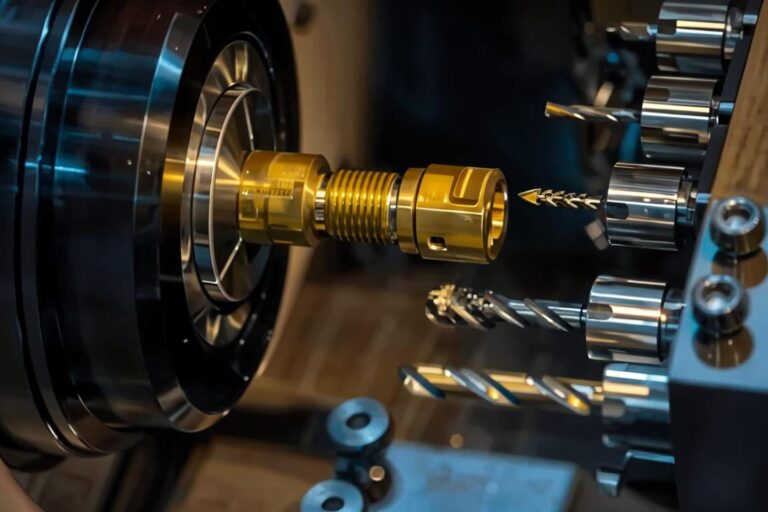

Machining and Manufacturing: Copper and Brass

Machining and manufacturing are essential processes for working with materials like copper and brass. Here’s a closer look at how these techniques apply to both metals.

- Copper Machining

Copper’s excellent thermal conductivity and ductility make it relatively easy to machine compared to other metals, although some challenges may arise. High-speed steel or carbide tools are commonly used, along with a continuous coolant supply to manage heat and extend tool life. It’s important to note that copper can “gall,” meaning material may adhere to cutting tools. This issue can be mitigated by using slower cutting speeds, maintaining sharp tools, and ensuring sufficient lubrication. - Copper Manufacturing

Copper manufacturing involves processes such as bending, cutting, and joining. Its ductility allows for extensive bending without breaking. Cutting can be performed via shearing or sawing, while joining methods typically include soft soldering, brazing, or welding. - Brass Machining

Machining brass is generally straightforward due to its low melting point and good machinability. It produces long, continuous chips, making the use of chip breakers highly recommended. Both high-speed steel and carbide tools work effectively when machining brass. - Brass Manufacturing

Like copper, brass can also be bent extensively without cracking due to its high ductility. Cutting brass can be accomplished through sawing, shearing, or even laser cutting. Joining brass components often involves brazing, soldering, or welding techniques, ensuring strong and reliable connections.

FAQ

How can I increase the productivity of CNC machining for brass parts?

To enhance productivity, it’s essential to use the appropriate tools, machining conditions, and equipment. Optimizing cutting parameters and employing efficient cooling systems can significantly boost production efficiency.

Is CNC machining of brass the right choice for my project?

Brass offers excellent mechanical properties that vary with zinc content. CNC machining is not only economical but also easy to handle, making it suitable for your needs. Share your specific component or product requirements, and our experienced engineers will be happy to assist. You can also refer to our CNC copper machining guide to help decide between brass and copper.

How do I choose the best brass alloy grade?

Selecting the right alloy grade depends on the application and required mechanical and physical properties such as hardness, strength, ductility, and conductivity. Given the unique characteristics of each alloy, it can be challenging to choose the best one. Our professionals can recommend the most suitable product based on your requirements.

What factors should I consider when selecting a brass grade?

Consider four key factors: corrosion resistance, strength, machinability, and appearance.

Do brass machined parts require surface finishing?

Most parts do not require post-coating treatment, but for decorative items, manual polishing can enhance the visual appeal.

How Can Leanplans Help?

We hope you enjoyed exploring the fascinating world of copper and brass with us and found answers to your questions about these intriguing metal alloys. If you’re embarking on a manufacturing project, Leanplans offers a comprehensive range of manufacturing capabilities and value-added services to meet all your prototyping and production needs.

Get started today by uploading your files to receive a free, cost-effective quote!