Custom Parts in Automation Equipment

With the rise of Industry 4.0, manufacturing is transitioning towards smart automation, making custom automation equipment essential for meeting specific operational needs. Custom parts provide flexibility and cost efficiency, especially as labor costs continue to rise.

Companies across various industries—such as electronics, automotive, and pharmaceuticals—are increasingly adopting automation, fueling the demand for tailored equipment. While standard parts may suffice for general applications, they often fail to address unique requirements, which is where custom parts excel.

In this guide, we’ll delve into the various types of automation equipment parts, highlight the benefits of custom solutions, and explain why our services for custom parts production are your best choice for enhancing equipment performance and longevity.

1. The Importance of Key Components in Automation Equipment

Automation equipment operates in highly complex production environments. From robots on assembly lines to precision assembly machines, the choice of parts directly affects performance, stability, and maintenance costs. Although standard parts can meet basic needs, custom components often offer better adaptability and efficiency in real-world applications.

Why choose custom parts?

Custom parts offer a strategic advantage by being specifically designed to meet the exact operational and performance needs of your equipment. Unlike off-the-shelf components, custom parts are engineered with precision, ensuring they perfectly fit within your system’s specifications. This tailored fit optimizes overall performance, enhances the reliability of your machinery, and significantly reduces the risk of costly downtime or failures.

For instance, in high-speed machinery, the constant wear and tear on standard parts can lead to frequent replacements and unexpected equipment failures, disrupting production and increasing maintenance costs. However, with custom parts, such as specialized gear systems made from high-durability materials like hardened steel or advanced composites, you can drastically improve longevity and reduce the likelihood of mechanical breakdowns. These parts are built to withstand the specific stresses and conditions your machinery faces, whether it’s high torque, intense pressure, or extreme temperatures.

Additionally, custom parts provide flexibility in material selection, surface finishes, and even design innovations. This level of customization allows manufacturers to address unique challenges such as corrosion resistance, lightweight construction, or vibration reduction. As a result, custom components not only ensure better compatibility with your equipment but also enhance its efficiency and lifespan, providing long-term savings by minimizing maintenance requirements and avoiding frequent repairs or part replacements.

Furthermore, investing in custom parts supports process optimization by fine-tuning critical aspects of your equipment. For example, custom-designed control components can improve precision in automated systems, enabling faster production cycles while maintaining product quality. This results in increased productivity, lower production costs, and a more efficient workflow.

2. Key Components of Automation Equipment

Automation equipment is composed of various essential parts that work together to ensure smooth operation and high efficiency. The primary components include transmission parts, drive components, sensors, fixtures, electronic elements, pneumatic cylinders, and control systems. Here’s a breakdown of each:

- Transmission Parts

These components are responsible for transmitting power from the drive system to the moving parts of the equipment. The key elements include ball screws, linear guides, sliders, couplings, and support seats. For example, rotating ball screws and linear guides ensure precision in movement, allowing for accurate positioning and control.

- Drive Components

Drive components typically consist of servo motors and drive controllers. The servo motor is responsible for power output, while the drive controller, composed of various circuits, control switches, and programming, governs the motor’s actions. Together, they control the power output and ensure the desired motion is achieved with precision.

- Fixtures (Jigs & Clamps)

Acting as the “hands” of the automation system, these parts enable the equipment to perform actions like gripping, holding, and positioning parts during production. Fixtures are critical for ensuring stable and repeatable processes, playing a crucial role in automating tasks such as assembly, packaging, and welding.

- Electronic Components

Automation systems rely on various electronic elements, including control panels, positioning switches, and circuit boards. These components act as the “nervous system” of the equipment, receiving input and processing it to generate the correct response, such as adjusting movements or stopping the machine when necessary.

- Pneumatic Cylinders

Pneumatic components such as air cylinders assist in handling tasks like picking, placing, or moving objects within the system. They provide mechanical motion powered by compressed air, working in conjunction with fixtures to enhance the machine’s versatility.

- Control System

The control system is akin to the “brain” of the automation equipment. It typically includes a programmable logic controller (PLC) and software that manages all machine operations. The control system is the heart of automation, responsible for executing programmed tasks, coordinating actions between components, and ensuring the system operates efficiently.

Additional Components Include:

- Pneumatic Elements: Pneumatic cylinders, solenoid valves, connectors, and air pipes, which work together to perform various air-powered functions.

- Electrical Elements: These include power supplies, circuit breakers, contactors, frequency converters, and control cabinets. These components manage electrical distribution, ensuring the smooth operation of the entire system.

- Mechanical Elements: Gearboxes, bearing housings, sliders, self-lubricating bushings, and tensioning sleeves provide the necessary mechanical stability and motion control within the equipment.

- Metal Materials: Common materials include steel plates, I-beams, rectangular steel, and round steel, which provide the structural framework for the equipment.

- External Processing: Processes like turning, milling, planing, plasma/laser cutting, gantry milling, and custom non-standard steel structure fabrication are essential for creating specific machine parts.

3. Why Choose Custom Parts?

The key advantage of choosing custom parts lies in the performance optimization and long-term savings they offer, which standard parts cannot always deliver. Here are some major benefits of custom parts:

- Better fit: Every piece of automation equipment is unique, and custom parts are designed to match the exact specifications, ensuring optimal compatibility and performance.

- Higher precision: In high-precision manufacturing, standard parts might leave room for error, whereas custom components are crafted to ensure accurate and reliable operation.

- Cost savings: While custom parts may have a higher upfront cost, they reduce maintenance needs, prevent equipment breakdowns, and minimize downtime, resulting in significant long-term savings.

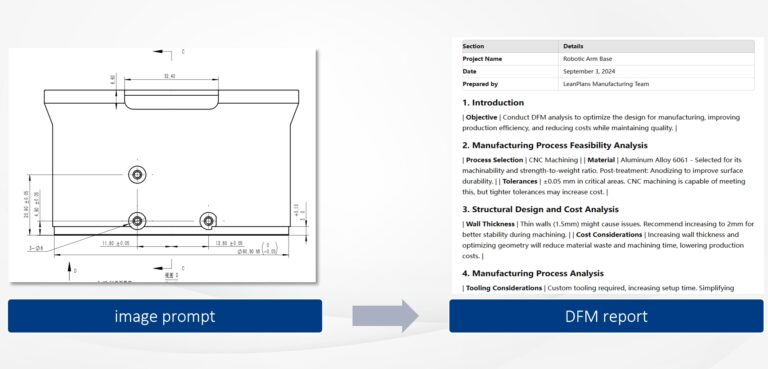

How can we help? Leanplans provides rapid custom parts services powered by AI technology. This allows you to get perfectly matched parts for your equipment, quickly and efficiently. Our AI system analyzes your needs and delivers an accurate quote in just 5 seconds, reducing waste in time and cost.

4. What Leanplans Offers

Leanplans specializes in custom parts production for non-standard components, offering comprehensive services from design to production:

- Multi-process support: Our services cover CNC machining, rapid prototyping, 3D printing, sheet metal, injection molding, and more. This ensures that whether your parts are complex or routine, we can provide the right solution.

- AI-powered instant quotes: With our AI-driven quoting system, you can upload your design and receive an accurate price within 5 seconds. This allows you to make quick decisions and respond rapidly to market needs.

- Flexible production: Whether it’s a small batch or a large-scale production, we can adapt to your needs and ensure timely delivery, keeping your supply chain stable.

5. Success Stories

Case 1: Custom Transmission System Improves Equipment Efficiency

We partnered with an industrial automation company facing significant challenges with equipment efficiency due to rapid wear and tear in their transmission systems during high-speed operations. The standard transmission components were unable to withstand the demands of their fast-paced environment, leading to frequent breakdowns and costly downtime.

To address this issue, our engineering team designed and produced a custom transmission system specifically tailored to the client’s operational requirements. Utilizing specialized materials and advanced engineering techniques, we created a robust solution that significantly enhanced durability and performance. As a result, the new transmission system reduced equipment downtime by 30%, allowing the client to optimize their production schedule and achieve a significant boost in overall production efficiency. This successful implementation not only improved their operational reliability but also underscored the value of investing in customized solutions to meet unique challenges.

Case 2: Customized Sensors Enhance Production Line Intelligence

In a highly complex manufacturing environment, one of our clients struggled with the limitations of standard sensors that failed to provide accurate data for monitoring critical production conditions. This lack of precision hindered their ability to make informed decisions and optimize their processes, leading to inefficiencies and increased production costs.

To overcome these challenges, we collaborated closely with the client to understand their specific monitoring needs. Our team then developed high-precision, custom sensors that were specifically designed to meet the complexities of their production line. These sensors featured enhanced sensitivity and accuracy, enabling real-time monitoring of various parameters such as temperature, pressure, and material flow.

The implementation of these customized sensors significantly improved data accuracy and increased the stability and intelligence of their production line. As a result, the client was able to make data-driven decisions, streamline their operations, and reduce waste. This case highlights how tailored sensor solutions can transform production processes and drive significant improvements in efficiency and productivity.

6. General Process for Customizing Non-Standard Automation Equipment

Customizing non-standard automation equipment is streamlined and efficient when combined with our services. Here’s how the typical process works, integrated with what we offer:

- Demand Analysis

We start with thorough communication to understand your specific requirements for the equipment. Our team will engage with you to discuss the intended use, performance metrics, dimensions, materials, and production efficiency. This step ensures we capture all necessary details to meet your unique needs.

- Design and Development

Once we have a clear understanding of your needs, we move to the design and development phase. You can easily upload your design through our online platform or reach out to our technical support team for assistance. Our experienced engineers will consider feasibility, reliability, and maintenance to create a custom solution tailored to your requirements. - Manufacturing and Assembly

With the designs finalized, we proceed to manufacturing and assembly. Using high-quality materials and components, we follow strict quality control measures to ensure the equipment meets performance standards. Our flexible production capabilities allow us to handle both small-batch and large-scale orders efficiently. - AI-Powered Quote

During the process, our system automatically analyzes your needs and provides an accurate quote within just 5 seconds. This quick response helps you make faster decisions and keeps the project moving forward without unnecessary delays.

- Debugging and Testing

After manufacturing, we conduct thorough debugging and testing to ensure that the equipment performs as intended. This critical step helps identify any potential issues, allowing us to deliver reliable and efficient equipment that meets your expectations. - Installation and Delivery

Once testing is complete, we ensure smooth installation at your specified location. Prior to delivery, we conduct a final inspection to confirm that everything meets your requirements. Our commitment to fast delivery means you can receive parts in as little as 48 hours, minimizing downtime for your operations. - After-Sales Service

After delivery, we provide ongoing support, including maintenance, servicing, and troubleshooting assistance. Our team is always available to ensure that your equipment operates optimally and to address any issues that may arise.

By integrating these services into the customization process, we ensure that the entire experience is efficient and transparent. You can quickly get the custom parts you need to keep your automation equipment running smoothly, allowing you to focus on your core operations without interruption.

7. Enhance Equipment Performance with Leanplans Custom Parts

In the world of automation equipment, custom parts can make a significant difference in improving efficiency, stability, and longevity. With Leanplans’ custom services, you get high-quality, precision-made components designed to perfectly meet your equipment needs. Our AI-powered quoting system and flexible production capabilities ensure that your projects are completed on time and on budget. Contact our team today to begin your custom journey!

Get a Free Quote!

Leave your contact details, or directly visit our online quoting platform to experience the future of material selection and production. Get expert material evaluations, tailored DFM analysis, and fast 24-hour production turnaround.

- Free Quote: Upload your designs, and our AI-powered engine will generate a custom quote in seconds.

- Talk to an Expert: Connect with one of our engineers via WhatsApp for immediate assistance.