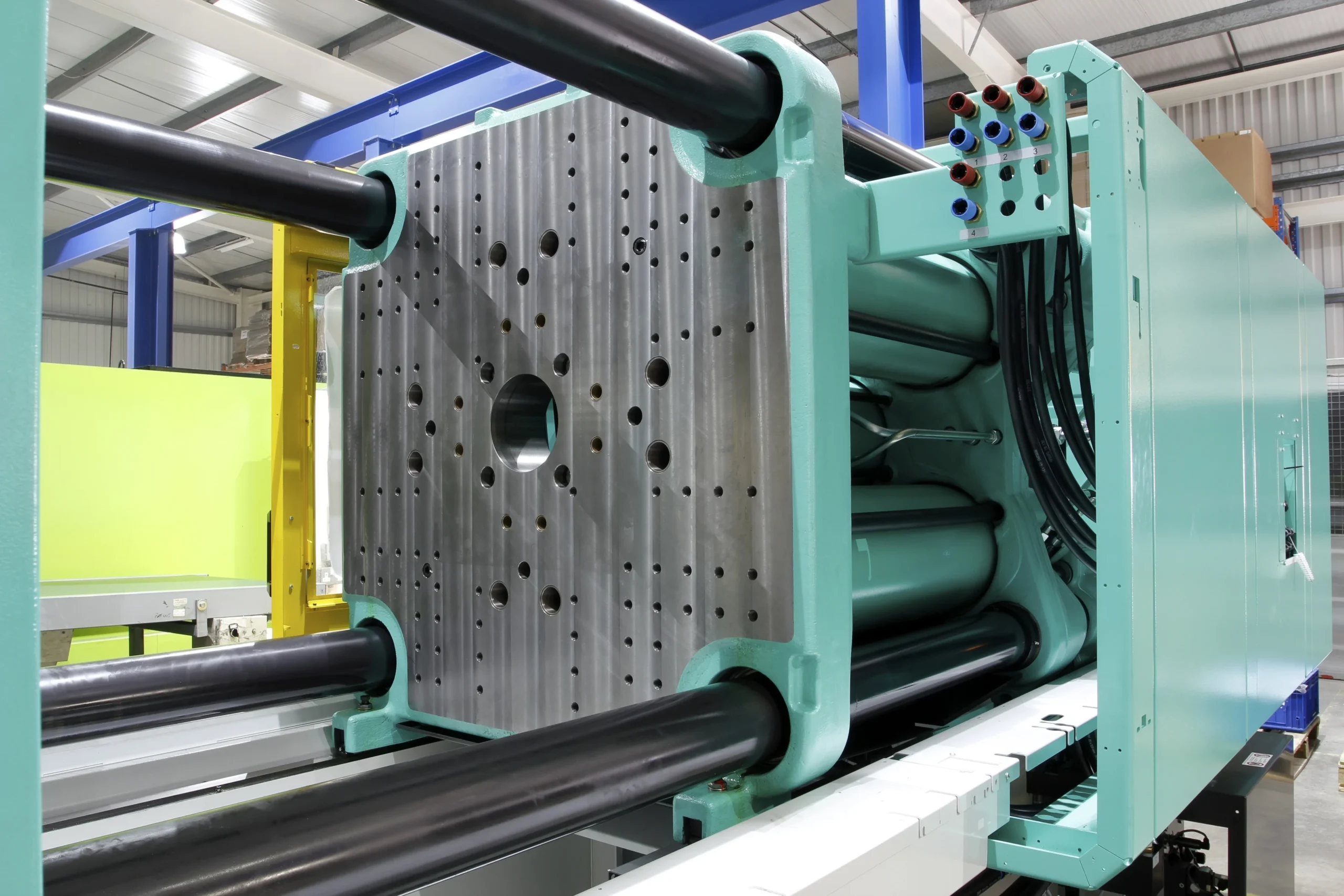

注塑工艺

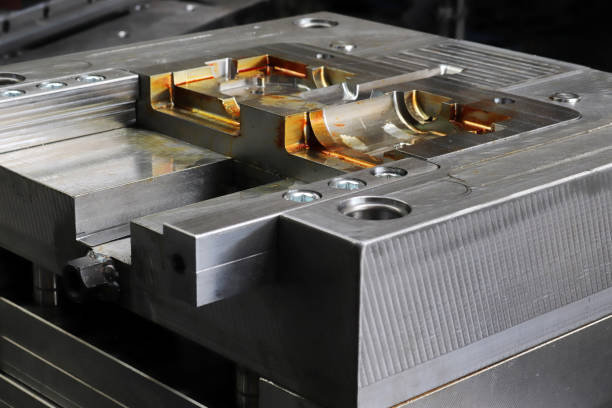

注塑模具

在大规模生产中至关重要,这一过程涉及从钢或铝材料中加工和组装耐用的模具,以确保部件几何形状的精确性和一致性。

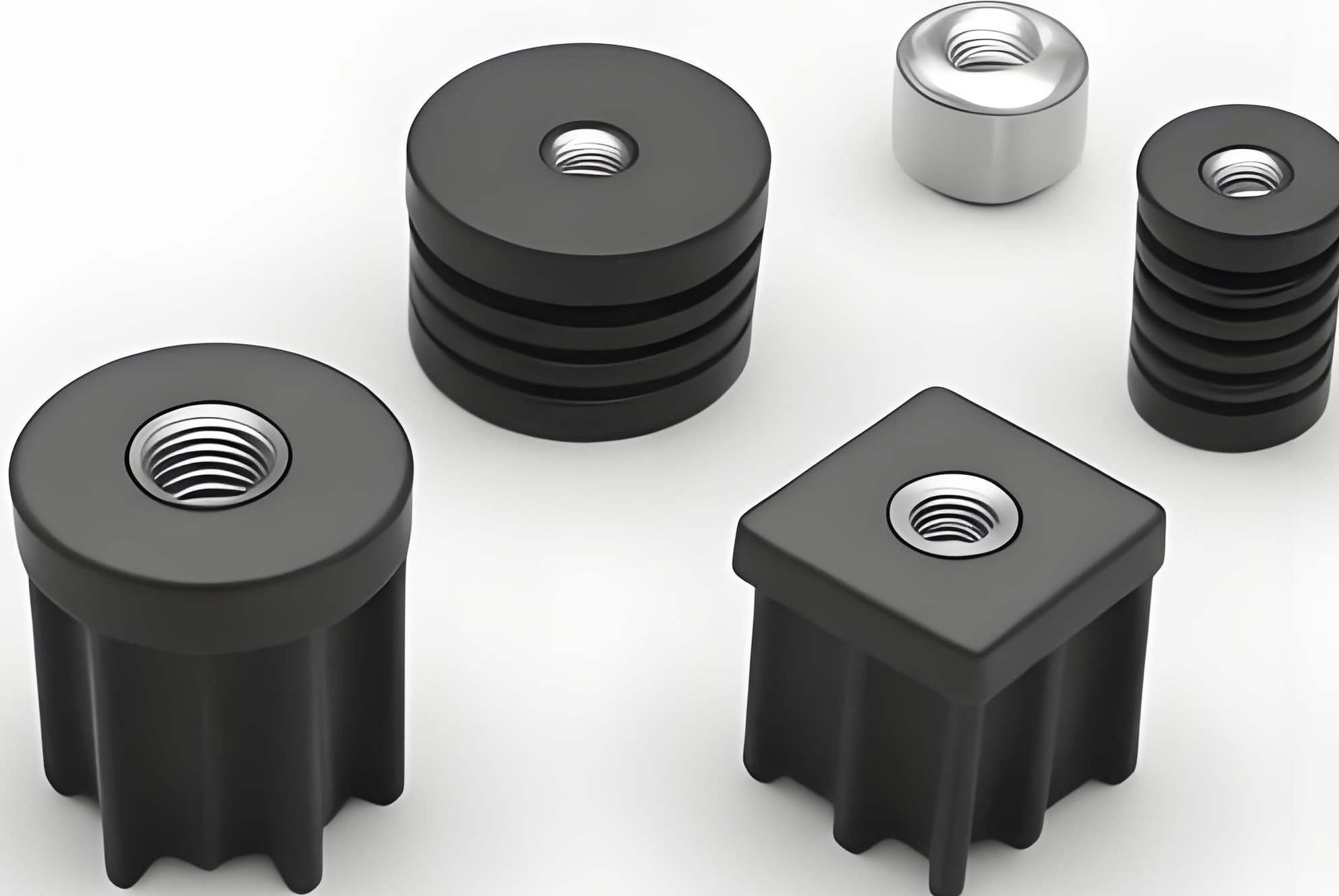

包覆注塑

通过将不同材料结合成一个部件来提升产品的功能性和美观性。该工艺增加了如柔软握把和多色设计等特性,提高了产品的可用性和视觉吸引力。

嵌入成型

嵌入成型在模具成型过程中将金属或其他材料嵌入塑料部件中,从而增强部件的强度,并减少带有内置功能组件的装配时间。

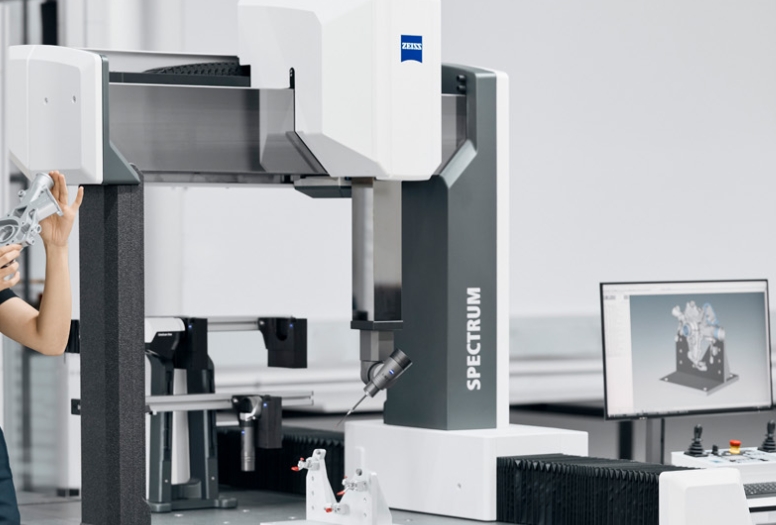

制造设备&检测设备

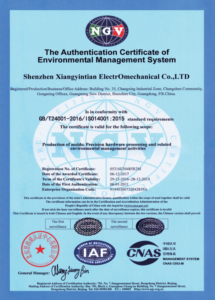

全球管理体系认证

业务流程

上传图纸

上传您的设计图纸,支持CAD图纸及常见的3D格式、PDF文档、图像格式;

补充需求

完善零件的加工材料、表面处理、数量等具体的生产需求;

报价下单

AI报价引擎出具报价方案,您确认无误后,即可下单支付;

生产交付

订单直达车间上产线,质检后送货上门,订单全链路可监控。

加工原材料

ABS(丙烯腈-丁二烯-苯乙烯)是一种广泛使用的热塑性塑料,因其优良的机械性能和多功能性而闻名。ABS以其耐用性、高冲击抵抗力和易于成型而受到重视,广泛应用于汽车部件和消费电子产品等领域。注塑的ABS产品通常具有优越的表面光洁度、尺寸稳定性和环境应力抵抗能力,成为许多制造商的首选材料。

PEEK(聚醚醚酮)是一种高性能热塑性塑料,因其卓越的强度、热稳定性和化学耐受性而著称。PEEK非常适合先进的航空航天、医疗和电子应用,即使在高温下也能保持其机械性能。注塑的PEEK部件提供长期耐用性、低水分吸收和出色的耐磨性,使其在严苛的工程环境中必不可少。

HDPE(高密度聚乙烯)是一种强度高、密度大的热塑性塑料,因其高强度与密度比而受到青睐。HDPE常用于容器、管道和地膜,因其冲击、湿气和化学耐受性而备受推崇。注塑的HDPE产品耐用、可回收,并能抵抗如紫外线辐射等环境应力,是追求持久和可持续解决方案的行业的首选材料。

PET(聚对苯二甲酸乙二醇酯)是一种透明、轻质的热塑性塑料,因其强度和优良的气体阻隔性能而闻名。PET常用于包装,尤其是饮料包装,提供类似玻璃的清晰度和卓越的抗破碎性。注塑的PET产品晶莹剔透、可回收,并对水和大多数化学品具有耐受性。

TPE(热塑性弹性体)结合了橡胶的柔韧性和热塑性塑料的可加工性。注塑的TPE产品以其弹性、韧性以及强大的紫外线和天气抵抗力而闻名。TPE具有广泛的硬度等级,提供了从塑料到弹性体的多种选择。灵活、耐用且可回收,TPE广泛用于需要柔软触感的应用,如握把、密封件和医疗设备。

尼龙(聚酰胺,PA)是一种多功能热塑性塑料,以其强度、耐用性和热阻性而著称。注塑的尼龙产品提供优良的机械性能、尺寸稳定性以及对化学品和环境因素的耐受性。其适应性和韧性使其在各种温度条件下的高性能应用中成为首选材料。尼龙广泛用于汽车、电子和纺织品领域,因其耐磨性和低摩擦系数而受到青睐。

聚乙烯(PE)是全球使用最广泛的热塑性塑料之一。聚乙烯因其易加工、化学耐受性和优良的湿气阻隔性能而具备广泛的应用。从塑料袋到刚性容器的多功能性,使其在各种行业和日常应用中都至关重要。注塑的聚乙烯产品耐用、可回收且适应性强。