Why Laser Engraving is a Game-Changer in Manufacturing

Looking for precision laser engraving services? Let us guide you through the process! At Leanplans, we specialize in laser engraving, offering top-notch solutions for both metal and plastic parts.

In 2023 alone, Leanplans has crafted over 50,000 custom parts using advanced laser engraving technology. Our expert team handles all kinds of complex and high-precision projects with ease. Ready to explore the possibilities? Read on to discover how our cutting-edge technology and dedicated professionals can bring your vision to life!

What is laser engraving?

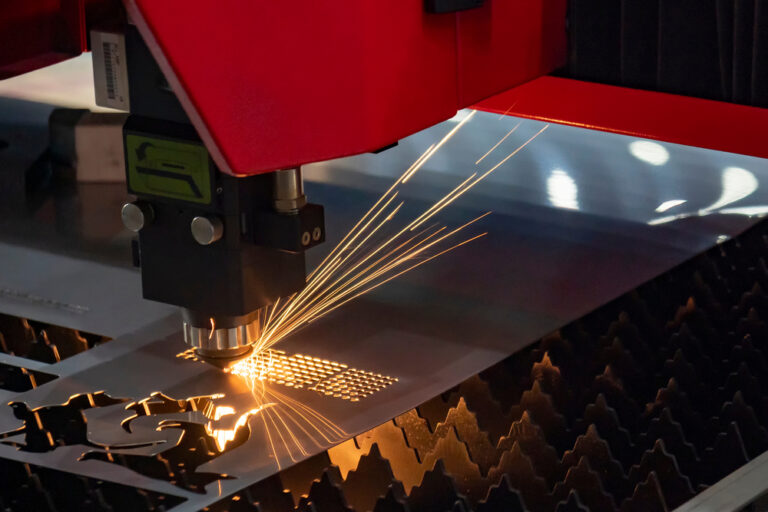

Laser engraving is a precise marking technique that uses a focused laser beam to vaporize the surface of a workpiece, creating a permanent pattern. A laser engraver is a type of laser marking machine that generates a laser beam to leave lasting marks on various materials.

As a core technology in laser marking, laser engraving stands alongside techniques such as etching, annealing, and ablation. While these methods share similarities in terms of precision, durability, and versatility with different materials, laser engraving excels in producing deeper, more durable, and higher-contrast markings.

The markings produced by laser engraving are typically deeper than those from other laser marking methods. The depth depends on both the material and the settings of the laser engraver. The strong contrast between marked and unmarked areas makes the engraving highly visible, though it may not be as pronounced as laser etching.

Laser engraving is widely used across industries for product traceability, identification, and decoration. It effectively marks logos, barcodes, serial numbers, and QR codes on a variety of parts and products.

A Brief History of Laser Engraving

Laser engraving technology traces its roots back to the 1960s when researchers at Western Electric Engineering Research Center introduced the first laser engraving machine. This pioneering system utilized a CO2 gas laser to etch and cut materials, setting the stage for future advancements. Over the years, improvements in laser technology, computer-aided design (CAD), and computer numerical control (CNC) have revolutionized laser engraving. These advancements have enhanced precision, speed, and versatility, making laser engraving a practical choice for various industries.

How Laser Engraving Works

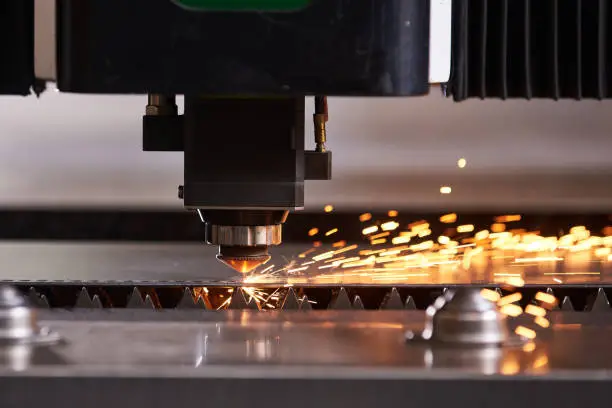

A laser engraver directs a laser beam onto the surface of the material. The energy from the laser heats the material, causing it to either vaporize or melt. Most laser engravers allow you to adjust both the depth and intensity of the engraving by modifying the power of the laser beam and the speed of the engraving process.

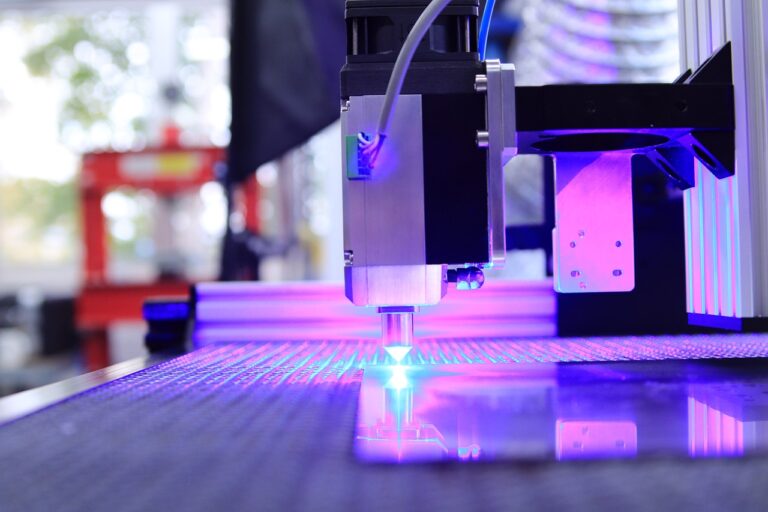

As technology progresses, the use of laser engraving in industrial applications continues to expand. One notable application is fiber laser technology for metal engraving, which is increasingly common in various industries.

With the principle of laser engraving established, you might be wondering: What are the steps involved in the laser engraving process?

Steps to Do Laser Engraving

1. Preparation

The preparation phase involves several important steps. Begin by conceptualizing the markings you want to engrave. Then, select the appropriate laser engraving materials based on your design and the compatibility with your laser engraver.

This step is crucial since laser engraving creates permanent marks on the material, making it difficult to modify once completed. Therefore, choosing a high-quality laser engraver is essential to ensure accuracy and durability.

2. Design

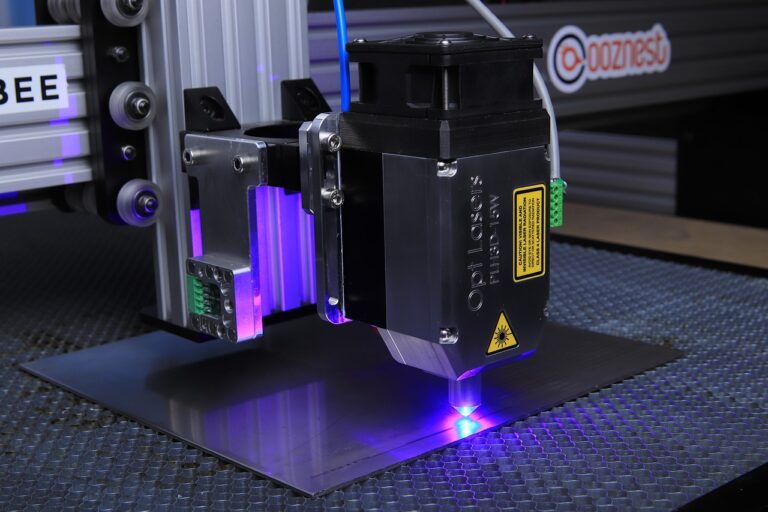

During the design phase, create a vector file for the laser engraving machine. This vector file will guide the laser in focusing the beams to produce the desired design or text. Various software packages can be used to create such files, including Adobe Illustrator, Inkscape, Lightburn, DraftSight, and Onshape.

3. Calibration

With your design ready, it’s time to set up the laser machine. Experiment with different laser parameters for optimal results. Adjust settings such as laser power, speed, cut depth, and line thickness to find the ideal combination for your project.

Technical Parameters:

- Maximum Engraved Area: 1000 x 8000 mm

- Speed: 0 to 88 m/min

- Minimum Text Size: 0.5 x 0.5 mm

- Positioning Accuracy: ±0.01 mm

- Supported Design Formats: BMP, HPGL (PLT), JPEG, GIF, TIFF, PCS, TGA, DST, DXF

4. Engrave

Direct the laser beam onto the material’s surface, where it vaporizes or melts the material to create your design or text. Most laser engravers operate on the X and Y axes, representing the horizontal and vertical directions on a flat surface.

Higher-end machines can also engrave along the Z axis, which allows for depth engraving and more complex, 3D designs. A movable table facilitates Y-axis engraving by moving back and forth while the laser head remains fixed, enabling larger surface area engraving. Quality laser engravers include software that coordinates with the machine’s motors for precise table movement.

Advanced Fiber Laser Engravers are ideal for creating intricate and personalized items, offering flexibility and precision. As AI technology continues to advance, future possibilities for laser engraving are promising.

5. Inspect

After engraving, inspect the material to ensure accuracy and proper alignment. Check for any residual material and clean the surface as needed to confirm that the design or text is correctly executed.

6. Surface Finishing

Enhance the appearance of the engraved material through finishing processes such as sandblasting, painting, polishing, anodizing, or coating. Depending on the material, these finishing touches can provide additional protection and aesthetic appeal.

Types of Laser Engraving Processes

Laser engraving can be categorized into three primary processes, each with distinct capabilities:

- Vector Engraving: In this method, the laser follows a continuous path, cutting or etching along the outline of a design. Vector engraving is perfect for cutting shapes, creating stencils, or engraving precise outlines. It produces sharp, clean edges, making it ideal for detailed projects.

- Raster Engraving: This process involves the laser moving back and forth across the surface, similar to a printer. Raster engraving creates a textured pattern by removing material in a series of closely spaced lines. It’s suitable for engraving images, shading, or filling large areas with detailed patterns.

- 3D Engraving: A more advanced technique, 3D engraving adjusts the laser power and speed to create varying depths, resulting in a three-dimensional effect. This process is used to produce relief images, sculpted surfaces, or intricate textures, adding depth and dimension to materials like wood, metal, or acrylic.

Advantages and Limitations of Laser Engraving

Advantages:

- High Precision: Laser engraving is renowned for its ability to produce intricate and detailed designs with high accuracy. This precision is particularly valuable for applications requiring fine detail, such as in jewelry or electronics.

- Non-Contact Process: Since the laser beam does not physically touch the material, it minimizes wear and tear on both the machine and the material, making it suitable for delicate or brittle items like glass or thin plastics.

- Versatility: Laser engraving machines can work with a wide variety of materials, including wood, metal, glass, plastic, and textiles. This versatility makes it an appealing choice for industries ranging from aerospace to fashion.

- Speed: Laser engraving generally operates faster than traditional methods, which enhances productivity and efficiency.

Limitations:

- Material Restrictions: Some materials, such as transparent glass or certain metals, may present challenges or require specialized equipment.

- Initial Cost: High-quality laser engraving machines can be costly, which may be a barrier for smaller businesses or hobbyists. However, the long-term benefits often outweigh the initial investment.

- Safety Concerns: Operating a laser engraving machine requires adherence to safety protocols, as the laser can cause severe burns or eye damage. Proper training and protective eyewear are essential.

Practical Applications: Hand knives

Fiber laser engraving has become an indispensable tool for small business owners, craftsmen, and entrepreneurs, offering unmatched precision, speed, and versatility. These machines enable a wide range of creative possibilities, transforming industries and helping businesses achieve growth and success.

Many small businesses find themselves constrained by the tools they use. Take Caren, a custom knife maker, for example. Her biggest challenge was adding intricate details and personalized engravings to her knives. After researching various technologies, she decided to partner with Leanplans. This decision revolutionized her workflow.

Anna designed elegant logos, brand initials, and complex patterns for her knife blades and handles, which were then laser-engraved by us. This collaboration resulted in the creation of unique, high-value products. As a result, Anna successfully attracted more customers seeking personalized items. The distinctive custom engravings set her apart from competitors and significantly boosted her business.

Conclusion

Laser engraving stands out as a sophisticated and adaptable technology with a range of applications across different industries. Its precision, speed, and ability to create detailed designs make it a valuable tool for personalizing items like acoustic panels and felts. Despite some limitations, the advantages of laser engraving, including its versatility and efficiency, make it a crucial technology in modern manufacturing and customization.

Get a Free Laser Engraving Quote!

Leave your contact details, or directly visit our online quoting platform to experience the future of material selection and production. Get expert material evaluations, tailored DFM analysis, and fast 24-hour production turnaround.

- Free Quote: Upload your designs, and our AI-powered engine will generate a custom quote in seconds.

- Talk to an Expert: Connect with one of our engineers via WhatsApp for immediate assistance.