Exploring the Frontier of Manufacturing – 5-Axis Machining Center

What is a 5-Axis Machining Center?

In modern manufacturing, the 5-axis machining center is a “Transformative force” driving technological innovation. Known for its high efficiency and precision, it has become the core force in solving complex component production challenges. A 5-Axis Machining Center is an advanced CNC machine tool capable of simultaneous multi-axis processing. By synchronizing the rotation and movement of both the workpiece and the tool, it efficiently completes intricate and precise machining operations. The 5 axes of the machining center are X, Y, Z, A, and C, each with the following functions:

- X-Axis: The horizontal movement of the workpiece (left to right), controlling the movement in the X direction to achieve the required machining.

- Y-Axis: The vertical movement of the workpiece (front to back), controlling the workpiece’s movement in the Y direction to match the machining needs.

- Z-Axis: The vertical movement of the workpiece (up and down), controlling the workpiece’s height adjustment for machining.

- A-Axis: The rotation of the workpiece around the X-axis, enabling horizontal rotational machining.

- C-Axis: The rotation of the workpiece around the Z-axis, enabling vertical rotational machining.

Through the coordination of these 5 axes, the 5-axis machining center can operate synchronously in multiple directions and angles, allowing for precise machining of multiple surfaces of the workpiece. This gives it a significant advantage when machining complex geometries and high-precision parts. Compared to traditional three-axis machining centers, the 5-axis machining center excels in the following aspects:

- Higher Precision: Frequent setup changes can disrupt your work and cause accuracy issues. When re-setting the workpiece, even small errors during placement can affect precision. The 5-axis machine easily solves this problem, eliminating errors from multiple clamping.

- Faster Processing Efficiency: Using a three-axis machine, multiple clamping and manual rotation of the workpiece are necessary to machine different surfaces. With a 5-axis machine, only one clamping is needed to process multiple surfaces, saving significant time.

- Wider Processing Range: With 5-axis CNC machining, complex curves and hard-to-machine materials can be easily handled. Traditional three or four-axis machines may struggle with intricate geometries such as curves and recessed areas, but 5-axis machines can process them effortlessly.

5-axis machining centers are widely used in industries such as aerospace, automotive, marine, mold making, and precision machinery. When manufacturing complex and curved parts, they not only significantly improve product quality but also reduce processes and fixture use, greatly enhancing production efficiency.

Our Machining Capabilities

1. Core Factory Focused on CNC Machining

We operate 5 core factories, with one dedicated exclusively to CNC machining. Our advanced facilities offer robust capacity:

- Number of Machines: 120 CNC machining centers, including:

- 3-Axis Machines: 80 units for efficient production of simpler components.

- 4-Axis Machines: 33 units for multi-surface machining, enhancing production efficiency.

- 5-Axis Machines: 7 units, ideal for manufacturing complex, high-precision parts.

- Brand of Equipment: We use leading brands such as Beijing Jingdiao, Makino, and Topstar, ensuring reliable machine performance and machining precision.

- Certifications: Our factories are ISO 9001, ISO 14001, and IATF 16949 certified, providing high-quality processing capabilities across multiple industries.

2. Technical Support and Team Strength

Our technical team has accumulated extensive machining experience and is proficient in operating top-tier equipment. We offer end-to-end services, from design optimization (DFM) to mass production.

Leveraging AI-driven processes and intelligent scheduling systems, we further enhance production efficiency to meet demands for short lead times and flexible production of diverse product varieties.

Process Showcase: 5-Axis Machining Applications

Case Study 1: Automotive Parts — Brake System Housing Inserts

- Background

A customer from the automotive industry needed to machine a complex brake system housing with high-precision hole placement and multi-surface inserts. Traditional processes couldn’t meet the required specifications. - Solution

- A 5-axis machining center was used to complete the machining in a single clamping, ensuring precision for coaxial hole alignment and complex surfaces.

- High-rigidity tools were used to machine the insert grooves, effectively controlling vibration and improving surface finish.

- Results

- Hole positioning accuracy reached ±0.01mm, with a 30% improvement in first-pass assembly success.

- The machining lead time was reduced by 70%, resulting in a significant cost reduction.

Case Study 2: Medical Parts — Meniscus Prosthesis

- Background

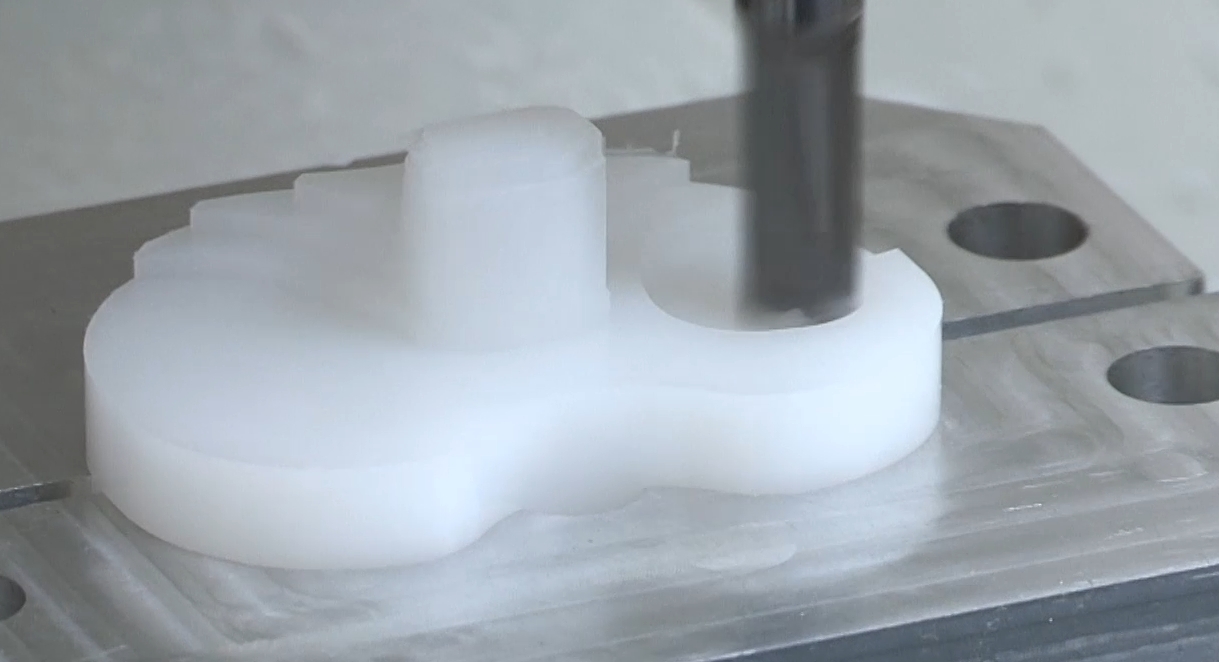

A medical industry client required a complex, bio-compatible meniscus prosthesis with highly precise surface finish and geometric accuracy. - Solution

- We used Beijing Jingdiao’s 5-axis machining centers, employing specialized tools for multi-angle, seamless machining to ensure the precise reproduction of the complex geometry.

- The lubrication process was optimized during machining, keeping the surface roughness below Ra 0.4, meeting medical-grade standards.

- Results

- The prosthesis passed clinical testing on the first attempt.

- Manufacturing efficiency increased by 40%, reducing the need for post-machining surface treatments.

Visit and Experience Invitation

- Transparent Factory, Leading Equipment

We invite you to schedule a visit to our factory and explore the practical applications of our precision machining equipment, along with our AI-enabled end-to-end solutions.

- Act Now

Contact us today for a customized machining proposal and begin your journey with us to create unique, high-quality components!

Get a Free Quote!

Leave your contact details, or directly visit our online quoting platform to experience the future of material selection and production. Get expert material evaluations, tailored DFM analysis, and fast 24-hour production turnaround.

- Free Quote: Upload your designs, and our AI-powered engine will generate a custom quote in seconds.

- Talk to an Expert: Connect with one of our engineers via WhatsApp for immediate assistance.