Material Selection for Smart Device Enclosures: Aluminum vs. Plastic

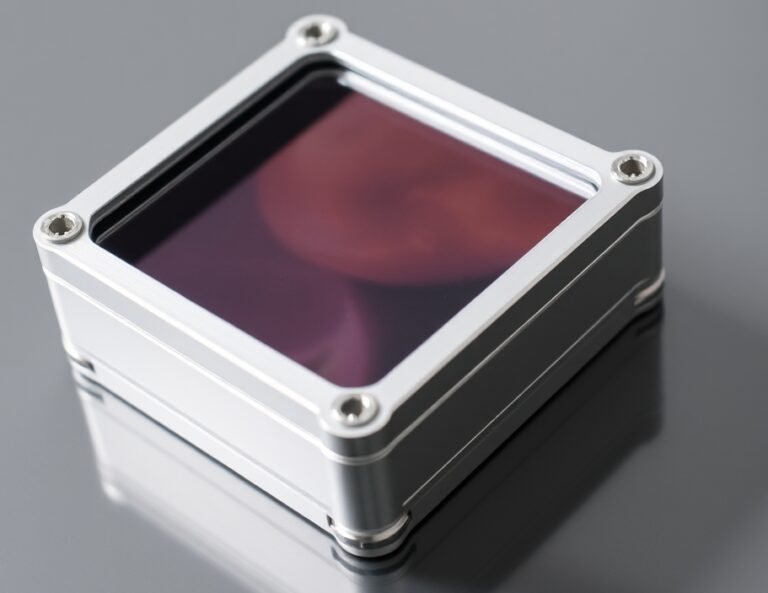

When it comes to designing and manufacturing smart devices, the choice of enclosure material significantly impacts durability, cost-efficiency, and user experience. Today, we’ll walk you through a real-world example that highlights the differences between aluminum alloy and plastic for smart device enclosures, comparing them in terms of durability, cost, and weight. We’ll also showcase how material selection influences the overall performance of the product.

1. Durability: Aluminum Alloy’s Superior Strength

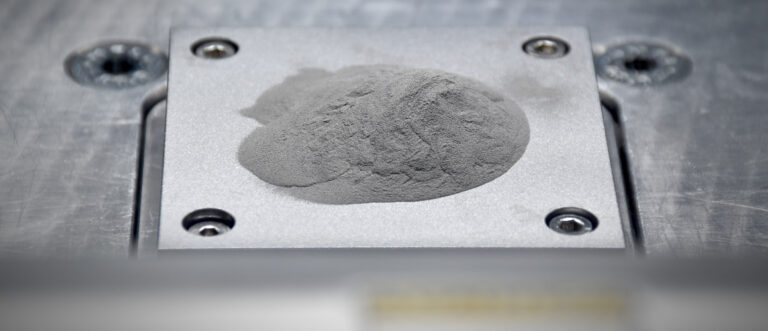

- Aluminum Alloy: Renowned for its high strength-to-weight ratio, aluminum alloy offers exceptional durability and corrosion resistance. It’s perfect for devices exposed to tough environmental conditions.

- Hardness: 2.5-3.0 on the Mohs scale

- Hardness: 2.5-3.0 on the Mohs scale

- Plastic: While plastic is more lightweight, it can be vulnerable to UV radiation and extreme temperatures, leading to potential wear and tear over time.

- Hardness: 0.5-2.5 on the Mohs scale, depending on the type

- Hardness: 0.5-2.5 on the Mohs scale, depending on the type

Our Expertise: If your product requires ruggedness and long-lasting durability, especially in challenging environments, aluminum alloy is the superior choice. For highly portable or indoor products, plastic may be sufficient, especially if cost is a key factor. However, for any application that demands high performance and longevity, aluminum offers unbeatable strength.

Whether you need a material for rugged, outdoor devices or cost-effective, lightweight alternatives, we tailor our solutions to your specific requirements. We provide detailed material analysis based on your product’s end-use environment to optimize its lifespan and durability.

2. Cost: Plastic’s Advantage in High-Volume Production

- Aluminum Alloy: While aluminum alloy offers premium durability, it comes with a higher price tag due to raw material cost and the CNC machining process.

- Cost per unit: Higher, especially for small runs and complex designs.

- Cost per unit: Higher, especially for small runs and complex designs.

- Plastic: In high-volume production, plastics—especially through injection molding—can significantly reduce unit costs.

- Cost per unit: Significantly lower for mass production, especially when using high-quality injection molding methods.

- Cost per unit: Significantly lower for mass production, especially when using high-quality injection molding methods.

Benefit to You: If you’re working on large-scale production and need to minimize costs, plastic is usually the more cost-effective solution. However, if your priority is ensuring premium product quality and you’re producing lower volumes, aluminum alloy might be the better investment in the long term, as its higher upfront costs can be offset by its extended product lifespan.

Depending on your product lifecycle and production volume, we can guide you toward the most cost-effective solution. Our advanced cost optimization algorithms help you achieve the perfect balance between performance and price.

3. Weight: The Importance of Lightweight Design

- Aluminum Alloy: Though lighter than steel, aluminum alloy is still heavier than plastic, making it less ideal for highly portable devices.

- Density: ~2.7 g/cm³

- Weight: Heavier than most plastic options

- Plastic: Offering significantly lighter options, plastic is ideal for devices where portability is a primary concern.

- Density: ~0.9-1.4 g/cm³

- Weight: Up to 50% lighter than aluminum, depending on the type of plastic.

Our Solution: For devices that require portability and ease of use, plastic is the clear winner due to its lighter weight. However, if strength and sturdiness are more important than portability, aluminum alloy is a better option as it combines reasonable weight with significantly higher durability.

We help you design for weight reduction without compromising structural integrity. Whether it’s through material selection or structural optimization, our engineering team ensures your device meets your weight requirements while maintaining performance.

4. Environmental Impact: Aluminum’s Sustainability vs. Plastic Alternatives

- Aluminum Alloy: Aluminum is 100% recyclable and does not degrade in quality during recycling, making it an eco-friendly choice for long-term sustainability goals.

- Energy use: Recycling aluminum uses 95% less energy than producing new aluminum from raw materials.

- Energy use: Recycling aluminum uses 95% less energy than producing new aluminum from raw materials.

- Plastic: Traditional plastics can have a significant environmental footprint. However, bio-based plastics and recycled plastics are emerging as eco-friendly options that help reduce the reliance on fossil fuels.

Our Commitment to Sustainability: If your company has strict environmental goals or is targeting eco-conscious consumers, aluminum alloy is the better option due to its high recyclability and low environmental impact. If cost efficiency is a higher priority, consider using recycled plastics or other sustainable plastic options to balance performance with environmental responsibility.

We offer comprehensive material options that align with your sustainability goals. Whether you’re looking for recyclable aluminum or environmentally-friendly plastics, we can provide materials that lower your carbon footprint.

Customization: Meeting Your Unique Needs

In addition to offering standard aluminum alloy and plastic options, we also specialize in material customization:

- Surface treatments: Anodizing, powder coating, and painting for aluminum. UV-resistant coatings and texturing for plastics.

- Color customization: Achieve the exact look and feel you want with our wide range of custom finishes and colors.

With ISO 9001 and IATF 16949 certifications, our services are designed to meet the highest standards, ensuring precision, quality, and scalability.

How Can We Help You?

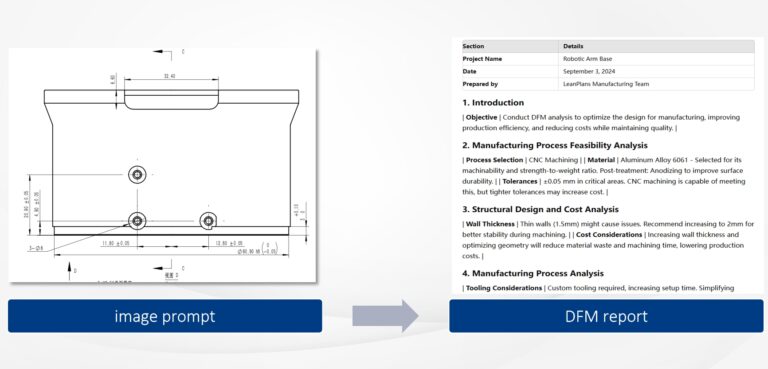

At Leanplans, we not only provide world-class materials, but we also ensure that your products are optimized for performance. Whether you’re designing an outdoor device needing rugged protection or a lightweight, portable gadget, our team of experts will offer personalized material assessments and free DFM & Quotes based on your design.

We’ve helped numerous international brands—from consumer electronics to aerospace—achieve cost-efficient and sustainable designs.

Get a Free Materials Assessment and Quote!

Leave your contact details, or directly visit our online quoting platform to experience the future of material selection and production. Get expert material evaluations, tailored DFM analysis, and fast 24-hour production turnaround.

- Free Quote: Upload your designs, and our AI-powered engine will generate a custom quote in seconds.

- Talk to an Expert: Connect with one of our engineers via WhatsApp for immediate assistance.