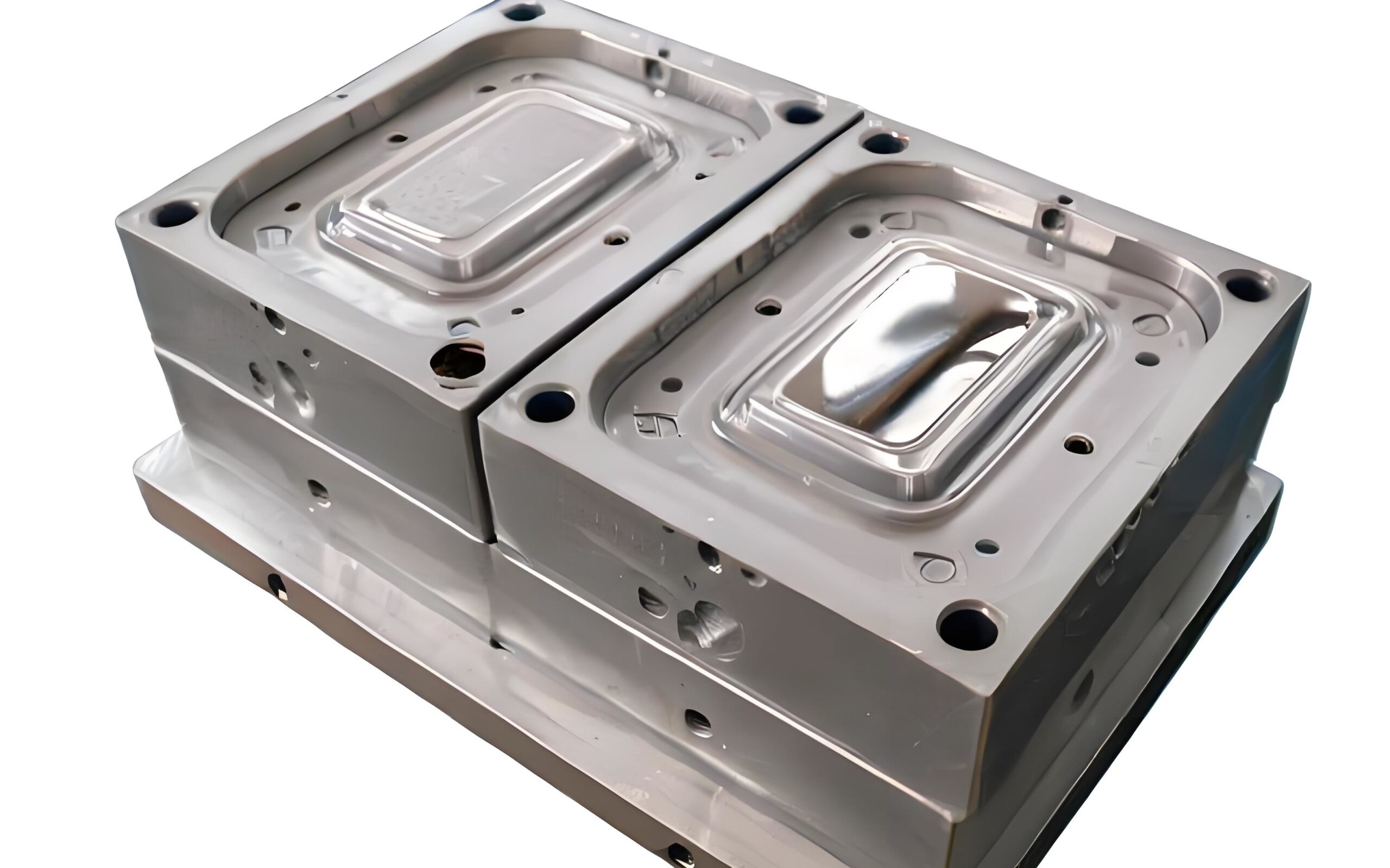

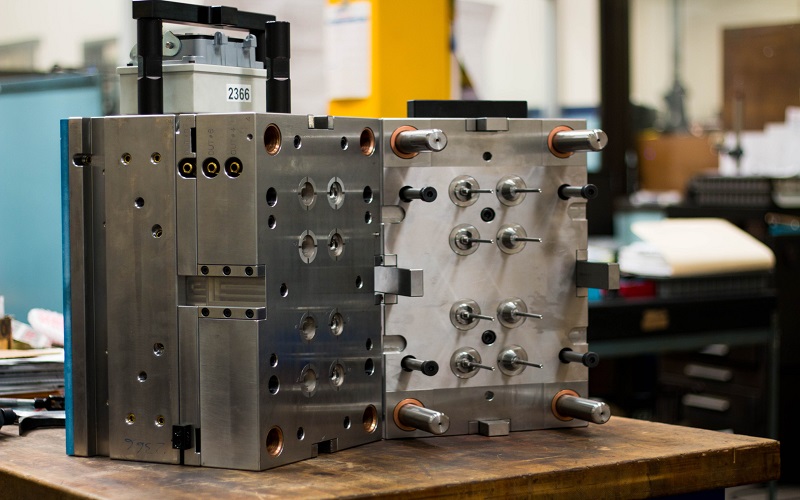

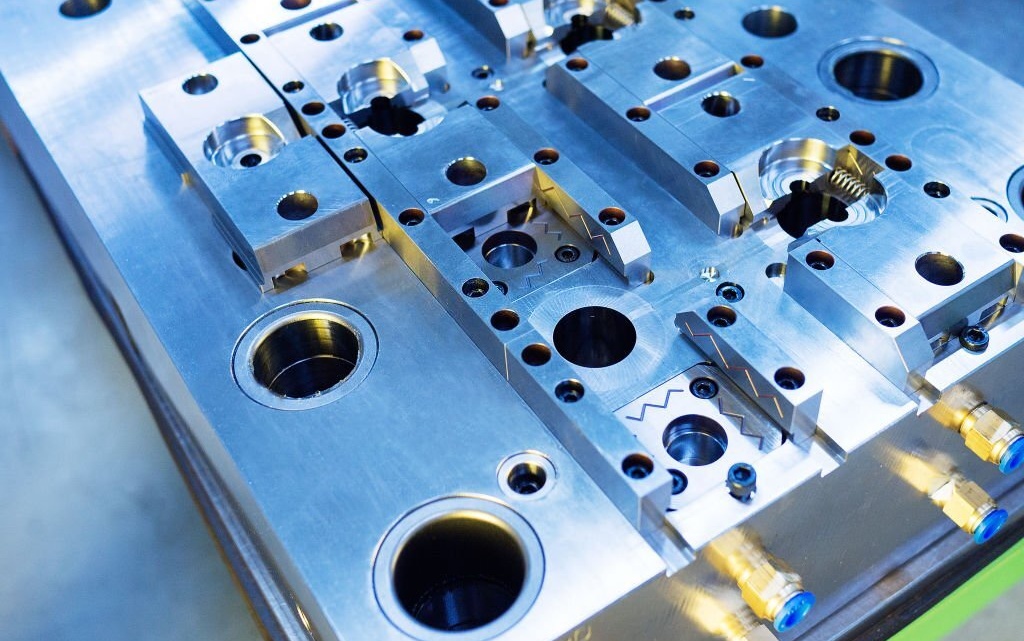

Mold Manufacturing

Although a production tool represents a larger investment compared to tooling designed for prototyping or limited-volume production, it's important to understand their differences. Leanplans use industry-leading techniques and processes in their high-volume injection mold tooling.

- Tight Tolerance of 0.02 mm

- The production will be completed in 10 days.

- ISO 9001, 14001, 22000 certifications

*All uploads are secure and confidential. Please check the PRIVACY POLICY.