快速打样服务

CNC快速打样

这种方法可以从完全致密的材料中制作原型,从而得到精确且耐用的模型。

注塑快速打样

高效地将设计转化为高质量的部件,适用于原型制作和大规模生产。

钣金快速打样

钣金加工非常适合快速生产需要以最终金属形态进行测试的平面部件。

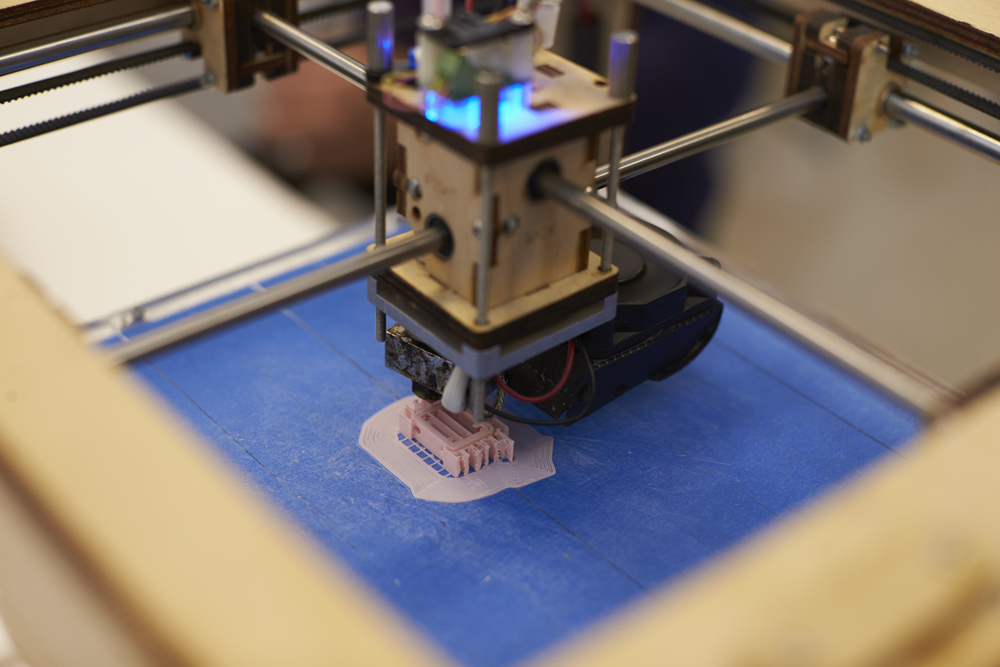

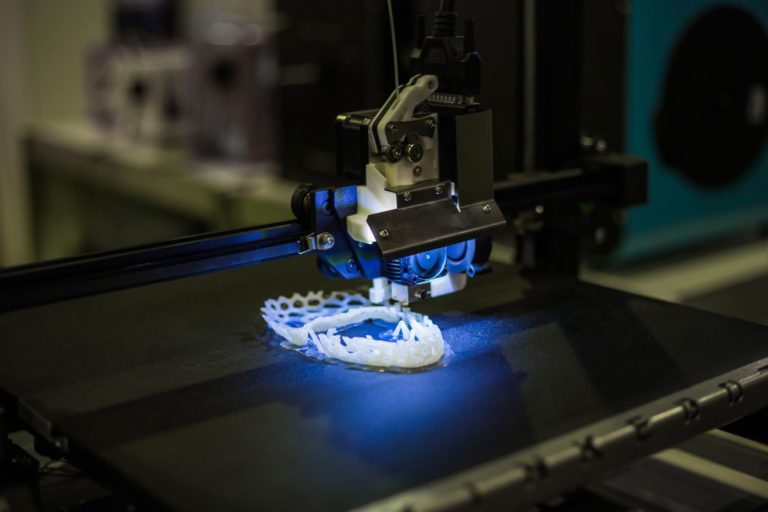

3D打印快速打样

用于快速原型制作的主要3D打印方法包括SLS、SLA和FDM。

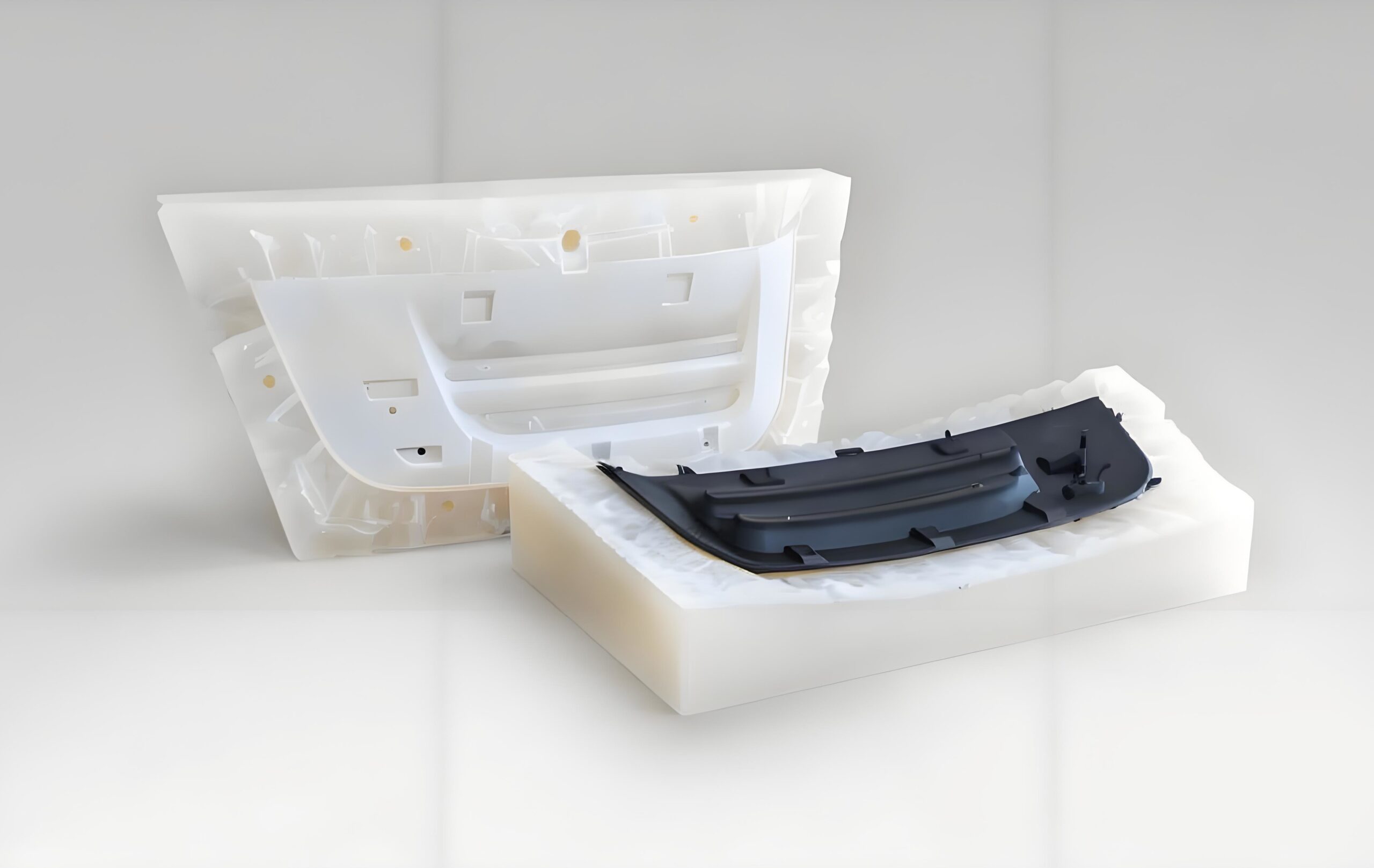

真空铸造快速打样

利用最先进的技术,我们迅速将您的设计转化为高质量且精确的产品。

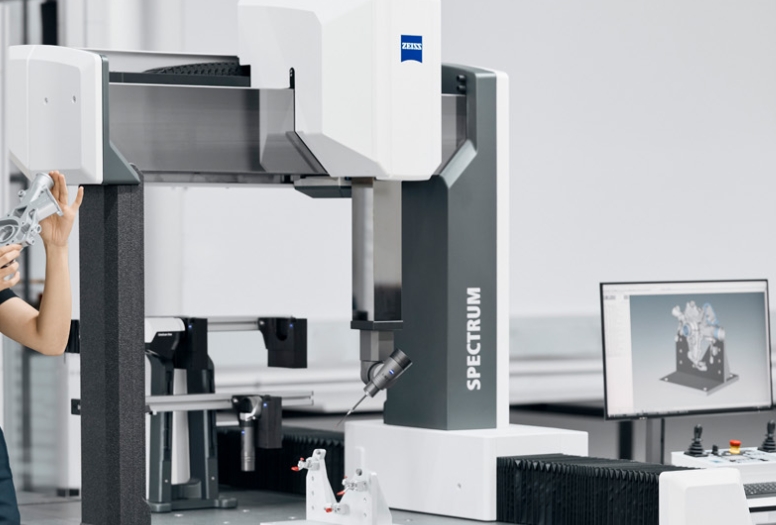

制造设备&检测设备

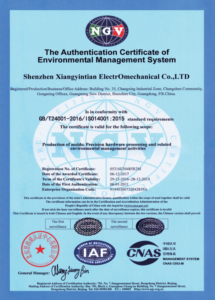

全球管理体系认证

业务流程

1

上传图纸

上传您的设计图纸,支持CAD图纸及常见的3D格式、PDF文档、图像格式;

2

上传图纸

上传您的设计图纸,支持CAD图纸及常见的3D格式、PDF文档、图像格式;

3

补充需求

完善零件的加工材料、表面处理、数量等具体的生产需求;

4

报价下单

AI报价引擎出具报价方案,您确认无误后,即可下单支付;

5

生产交付

订单直达车间上产线,质检后送货上门,订单全链路可监控。

加工原材料

| 材料分类 | 具体材料名称 | 主要特性 | 适用领域 |

|---|---|---|---|

| 金属 | 铝合金 (Aluminum) | 轻量、强度适中、导热性好 | 航空航天、汽车、电子器件 |

| 不锈钢 (Stainless Steel) | 耐腐蚀、强度高、耐高温 | 汽车零件、医疗器械、工业零件 | |

| 黄铜 (Brass) | 良好的导电性、耐腐蚀、易加工 | 音乐器件、电气连接件、装饰品 | |

| 钢铁 (Steel) | 强度高、多种类型适用,可钝化处理 | 结构零件、工业设备、汽车零件 | |

| 钛合金 (Titanium) | 强度高、轻量、耐高温、生物相容性好 | 航空航天、医疗植入物、汽车零件 | |

| 塑料 | 聚丙烯 (Polypropylene) | 轻质、刚性、耐化学腐蚀 | 包装、零件、家居用品 |

| 聚乙烯 (Polyethylene) | 耐化学腐蚀、耐磨损、耐低温 | 容器、管道、电缆绝缘 | |

| 聚氯乙烯 (PVC) | 耐腐蚀、电绝缘性好、可加工性高 | 管道、电线套管、装饰材料 | |

| 聚苯乙烯 (PS) | 轻质、硬度适中、绝缘性好 | 包装、家居用品、模型制作 | |

| 聚对苯二甲酸乙二醇酯 (PETG) | 耐冲击、透明、易加工 | 零件、容器、电子外壳 | |

| 复合材料 | 碳纤维复合材料 (Carbon Fiber Composite) | 高强度、轻量、耐腐蚀 | 航空航天、运动器械、汽车零部件 |

| 玻璃纤维复合材料 (Glass Fiber Composite) | 良好的强度和刚度、抗磨损 | 航空航天、船舶、汽车零部件 | |

| 聚合物复合材料 (Polymer Composite) | 强度高、轻量、耐磨损 | 航空航天、汽车、运动器械 |

表面处理

| 表面处理方法 | 具体方法名称 | 主要特点 |

|---|---|---|

| 砂磨 (Sanding) | 手工砂磨 (Hand Sanding) | 用砂纸或砂布手工磨去不平整或粗糙的表面。 |

| 机械砂磨 (Mechanical Sanding) | 利用机械设备进行高效的表面砂磨,提高一致性。 | |

| 抛光 (Polishing) | 机械抛光 (Mechanical Polishing) | 使用抛光机械和磨料将表面磨光,增加光泽度。 |

| 化学抛光 (Chemical Polishing) | 使用化学溶液去除表面粗糙,得到光滑表面。 | |

| 喷砂 (Sandblasting) | 喷砂除锈 (Sandblasting Rust Removal) | 利用高压喷砂将表面氧化层和锈蚀物去除。 |

| 玻璃珠喷砂 (Glass Bead Blasting) | 使用玻璃珠喷砂剂获得均匀、亮丽的表面。 | |

| 电镀 (Electroplating) | 镀铬 (Chrome Plating) | 在表面镀一层铬以提高耐腐蚀性和外观。 |

| 镀镍 (Nickel Plating) | 在表面镀一层镍以增强硬度和耐磨性。 | |

| 镀金 (Gold Plating) | 镀一层金属以提供美观的金色外观。 | |

| 喷涂 (Painting) | 喷漆 (Spray Painting) | 使用喷枪喷涂油漆,提供均匀的颜色和保护。 |

| 粉末涂装 (Powder Coating) | 使用静电将粉末喷涂在表面,形成坚固的涂层。 | |

| 热处理 (Heat Treatment) | 淬火 (Quenching) | 通过快速冷却来改善金属的硬度和强度。 |

| 回火 (Tempering) | 通过加热和冷却来减轻淬火效果,提高韧性。 | |

| 正火 (Annealing) | 加热和缓慢冷却以改善金属的可加工性。 | |

| 防腐涂层 (Coating) | 防锈涂层 (Anti-Rust Coating) | 添加防腐剂的涂层,提高材料的耐腐蚀性。 |

| 防划涂层 (Anti-Scratch Coating) | 抗划伤涂层提供保护和外观改善。 |